Mango pulp being processed for solar drying at Society for Energy, Environment and Development (SEED); (extreme right) Shyamala Rambhotla | Photo Credit: Nagara Gopal

Helmed by 94-year-old Prof Ramakrishna Rao, SEED’s zero carbon emission solar cabinet dryers may have answers to counter post-harvest losses

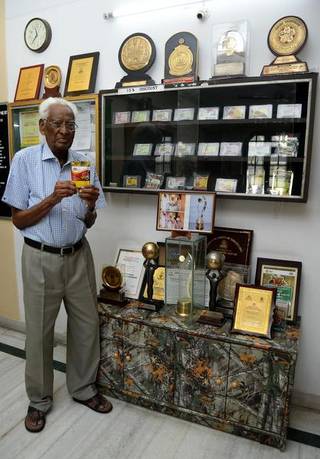

Professor M Ramakrishna Rao is 94. Yet, the retired scientist from Indian Institute of Science (IISc) in Bengaluru, is the tour de force of Society for Energy, Environment and Development (SEED), which he established 32 years ago. Drawing from his expertise in physics and renewable energy, he guided the research and development team to design solar cabinet dryers for food processing. Three hundred of these cabinets ensuring zero carbon emissions are being used in 19 states across India by organisations working in the agriculture sector.

Germination of SEED

Prof Ramakrishna Rao | Photo Credit: Nagara Gopal

Ramakrishna Rao spends his days at the SEED office and incubation centre in Hyderabad , overseeing the operations. He ascends the stairs, one step at a time, to inspect dryers on the terrace. Age may have slowed him down but he’s always enthusiastic to discuss how solar dehydration can help minimise post-harvest losses and develop food products that can fetch farmers additional revenue.

Rao founded the organisation in 1987, after retiring from IISc, eager to use his scientific knowledge to help the farming sector. He did his Masters in physics and PhD from Osmania University, followed by post-doctoral studies in Columbus University, Ohio. SEED is a non-governmental organisation with a governing council headed by Padma Vibhushan awardee Prof Palle Ramarao; several food scientists work in honorary positions. The organisation receives partial funding from Department of Science and Technology (DST), Government of India, and has 20 employees.

Helping Rao at SEED is his niece Shyamala Rambhotla, a computer science quality engineer. She returned to India in 2011, after working in a credit bureau in the US for 20 years, to help Rao with his work, and a long-term focus on strengthening the organisation.

In its first decade, SEED developed and tested dryers that used biomass and alternative fuels before zeroing in on solar cabinet dryers. Their solar cabinet dryer design was patented in 1997. The organisation reached out to those working in the agriculture sector to raise awareness about using solar power. It was a slow process. “Not many people knew about using solar power back then. We’ve seen a spurt in the last four years,” says Shyamala.

Branching Out

- SEED has worked on 100 fruits, vegetables and other produce. Solar dehydrated mango, pineapple, chikoo, guava, fig, mango and mixed fruit are sold as rolls or fruit bars. An environmental chamber checks the shelf life of food products. Some of the products are sold at Karachi Bakery outlets. However, SEED primarily remains a non-profit, research and development outfit.

- The centre’s library and lab is frequented by food science students for their projects. The organisation’s think tank comprises like-minded researchers and scientists. SEED also has an extension centre at Tholkata village near Moinabad.

- Six commercial solar cabinet dryers were exported to Australia, Indonesia, Mauritius, Saudi Arabia, Zanzibar and Kigoma.

Outreach initiatives

SEED has so far conducted 70 training sessions for more than 2,000 farmers, teaching them techniques of solar-drying fruits, vegetables, millets and other produce. A dedicated team develops products. On the day we visit the centre, ripe mangoes have been pulped, transferred as thin layers to trays and placed in the cabinets. A temperature gauge indicates 65° Celsius in the cabinet; another gauge monitors the weight reduction due to dehydration. It typically takes a day for the pulp to dry into a thin film; another layer of pulp is then added and left to dry. The dried pulp is then cooled, cut into segments and packaged as bars or rolls. “Traditional ‘mamidi thandra’ (aam papad) is made by drying mango pulp in open air, prone to dust. Solar cabinet drying ensures hygiene and retains nutritional value,” says Shyamala.

Fruit rolls developed by SEED | Photo Credit: Nagara Gopal

Other solar dryers are stocked with finely diced carrots, amla, spinach, rings of onions and tomatoes. An in-built fan removes moisture and ensures uniform dehydration. For leafy vegetables, the solar dryer is fitted with a blue filter to create greenhouse effect that helps retain chlorophyll and hence, the colour. “Dehydrated vegetables can be stored for later use. Soak it in water for 30 minutes and use for cooking just like fresh vegetables,” she says.

SEED designs dryers with loading capacities of eight, 50, 100, 200 and 500 kilograms and is working towards designing a one tonne capacity dryer for use in large firms. Elaborating on the applications, Shyamala explains, “Farmers incur losses when there’s a sudden drop in price, transportation issues or excess seasonal produce. At the mandal level, if community solar dryers are set up with government or corporate help, it will help farmers dehydrate their produce for later use and develop food products. India is big on agriculture production, but we aren’t processing enough.”

A dryer of eight kilograms capacity is priced at ₹40,000 and it goes up to ₹4,50,000 for 200 kilograms. SEED allows entrepreneurs to try the solar dryers at the incubation centre, develop their recipes and test market before purchasing. The pricing remains an issue, admit Rao and Shyamala. “If banks or the government can give subsidies, more farmers will be willing to buy,” says Shyamala. Rao points out that unlike electric dryers, solar dryers don’t have recurring costs.

Solar cabinets are efficient all through the year, barring occasional rainy days. “On such days, we use electric backup (powered by rooftop solar panels). We are working towards developing dryers that can use biogas for power backup,” sums up Shyamala.

(Planet Healers celebrates eco-conscious initiatives. If you know an eco warrior, writer in to hydmetroplus@thehindu.co.in)

source: http://www.thehindu.com / The Hindu / Home> News> Cities> Hyderabad – Planet Healers / by Sangeetha Devi Dundoo / April 22nd, 2019